Bentonite rock business Purchase Price + Quality Test

Bentonite rock has specific physical and chemical properties

Its business has flourished due to its special properties

Bentonite is a kaolin clay mineral composed primarily of montmorillonite mixed with the related minerals nontronite and beidellite

These are three layers of aluminosilicate with water molecules between the layers

Bentonite is a clay composed primarily of smectite minerals, usually formed from the decomposition of volcanic ash or tuff, or sometimes other igneous or sedimentary rocks

Bentonite

Bentonite is a highly plastic clay that shrinks (or swells) significantly in response to the removal (or addition of) water For natural sodium bentonite, exchangeable sodium cations predominate over other cations such as calcium and magnesium

Similarly, calcium cations predominate in calcium bentonite

Of all the bentonites available in the world, the sodium variety has the characteristics of high swelling and crystallization properties, good viscosity, and good fluid limit

A variety of bentonite found in different regions in the world

It was probably formed millions of years ago from volcanic ash that fell into stagnant saline water in semi-arid conditions

Due to the natural properties of this volcanic ash, the chemical composition of this particular variety is different from the rest of the world

Most of these deposits are natural sodium bentonite with a higher iron content

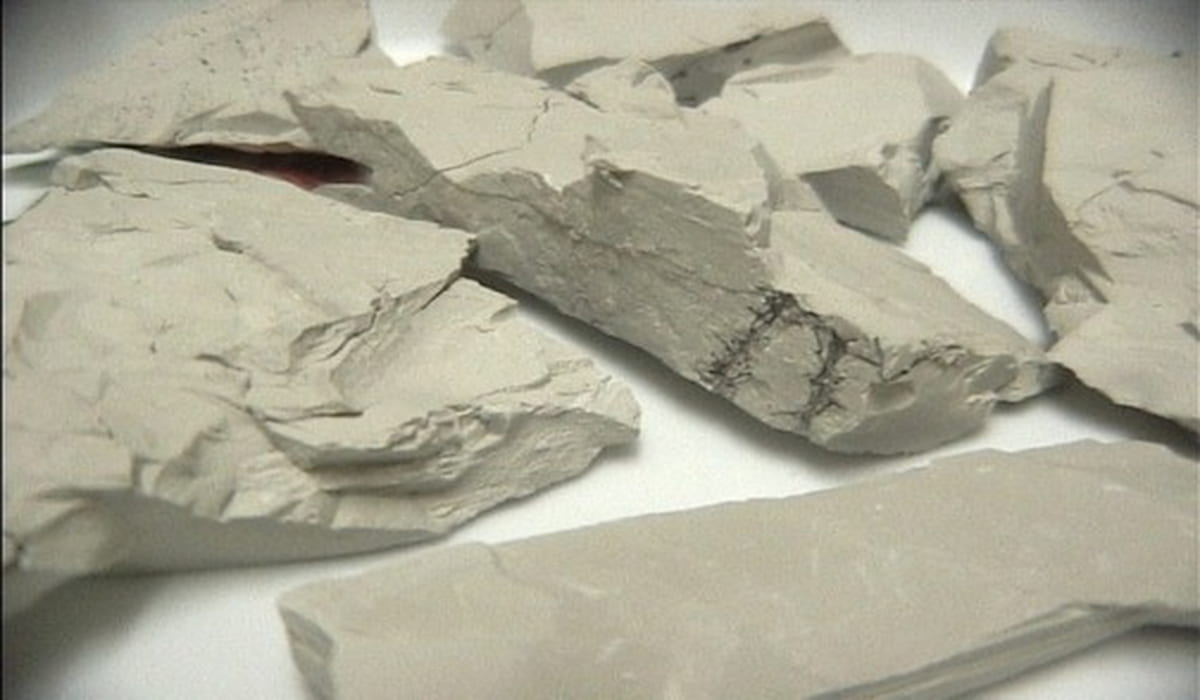

Darker in color and with a very fine particle size, this clay mineral exhibits extraordinary bulking capacity and bond strengths

These properties make bentonite applicable in various industries around the world

Moderate swelling of bentonite (average sodium and calcium)

Sodium bentonite is the most beneficial because of its high ability to swell

They are mainly used as binding mud in foundries, drilling mud, animal feed pellets, and for civil engineering applications

There are three main types of bentonite: high bloating (sodium) low bloating (calcium)

Bentonite powder trade

betonamit vs dexpan

For miners betonmit powder vs Dexpan is about the non-explosive agents present in both minerals

Splitting rock, crushing concrete, mining and extracting stone can be done by betonmit and Dexpan

It has never been easier with Dexpan non-explosive expansive demolition grout, which has been used successfully on hundreds of projects (see galleries below)

Dexpan is a powder with an amazing 18,000 psi strength when mixed with water

After pouring into pre-drilled holes, Dexpan can safely and quietly crack concrete and rock while providing silent cracking

It is safe, easy and profitable

Non-explosive destructive agents are chemical substances that replace explosives and gas pressure detonation products in demolition, mining and quarrying

[1] To use non-explosive destructive agents in demolition or quarrying, holes are drilled into bedrock as if using conventional explosives

A thick mixture of non-explosive destruction agent and water is poured into the drill holes

Over the next several hours, the suspension expands, cracking the rock in a pattern somewhat similar to the cracking that would occur with conventional explosives

Betonamate is a non-explosive demolition agent that allows for relatively accurate demolition without the need for special conditions or equipment

It has a very good shelf life of at least 3 years

After a reaction time of only a few hours, the betonamite develops an enormous expansion pressure, which soon becomes so strong that all hard rock and even reinforced concrete crack

Compared to other traditional demolition methods, Betonamit operates almost silently, is vibration-free and is environmentally friendly

Non-explosive destroyers like betonamate and Dexpan offer many advantages, including that they are quiet and do not produce vibrations like conventional explosives do

In some applications, conventional explosives are cheaper than non-explosive destruction agents

These are available in many countries without restrictions, unlike explosives which are highly regulated

These agents are safer than explosives, but must be used as directed to avoid vapor explosions during the first few hours after placement

Bentonite powder uses

betonamit for sale

Betonamit price for sale with the weight of 12 pounds is $54

50

BETONAMIT, a high-volume cracking agent, is supplied in powder form and sealed in easy to use 5kg plastic packs

It must be mixed with a specified amount of clean, cold water and poured into pre-drilled holes in the material to be shredded

After a few hours of reaction, BETONAMIT exerts a tremendous expansion pressure, which increases rapidly to the point that any solid rock, ordinary or reinforced concrete, can break

BETONAMIT can be used indoors and outdoors, in dry or wet conditions, even under water

Bentonite is a non-explosive demolition agent that enables the safe and earthquake-free crushing of rock, stone and concrete without the need for infrastructure or special preconditions

The betonamate has a very good shelf life of at least 3 years and can be sent by parcel without any problem

After a reaction time of only a few hours, Bentonitesodium develops an enormous expansion pressure that quickly becomes so high that it splits all solid rock and iron concrete

Compared to conventional blasting methods, bitonamite operates with virtually no noise, no vibrations and no flying debris

The following list is the list of its common properties

A product to cover all temperatures (from 5°C to 35°C) The package contains bags of betonamate from 4 kg to 5 kg The best performance per kg

The shelf life is not less than 3 years

Environmentally friendly due to natural raw materials

International for rocks, stone, concrete and iron concrete More than 40 years of experience in the field Free and professional support

Product of the highest quality and reliability

For use in all temperatures up to 35°C The strongest product on the market

Sodium bentonite powder

physical properties of bentonite

Among the most important physical properties of bentonite, which is used in many different industries, are the following: Water absorption and swelling

The basic property of bentonite is water absorption and expansion

However, not all bentonite has the same absorbent capacity

Its level of hydration and plumpness depends on the type of interchangeable ions it contains, with different capacity for water and solution

The swelling is mainly due to two factors: 1) water uptake at the platelet surface level and 2) extrusive osmotic forces, which force the platelets to separate and open up like a “stack of cards”

Sodium bentonite, with a predominance of sodium cations (Na +), allows water to penetrate the platelets, forcing them to separate, causing swelling

On the contrary, calcium bentonite mineral, with a predominance of calcium cation (Ca2 +), although it moisturizes in the same way, due to its strong positive charge, it has lower absorption properties, which prevents water from penetrating the platelets

In the latter case, platelets slough off rather than swell

Viscosity and thixotropy of aqueous suspensions When bentonite disperses in water, colloidal suspensions of high stability, high viscosity and liquefaction are formed

At sufficiently high concentrations, these suspensions begin to acquire gel properties

Suspensions are formed when water molecules penetrate the middle layers of platelets

Here, hydrogen bonds are made up of hydrogen atoms present in water molecules

Platelets separate from each other, while they join through the intervening water

When left still, a network is formed, with the merging of water, gels

Instead, under mechanical stress, these bonds partially break, allowing platelets to move more freely

The viscosity under these conditions is lower than at rest

This reversible sol-gel-sol process is known as thixotropic

These properties shown by aqueous bentonite suspensions are mainly used in drilling muds

Colloidal and waterproofing properties

When bentonite absorbs water, it forms a semi-solid gel with strong resistance to hydrostatic pressure

A sheet of montmorillonite can be decoded as a thin bundle of negatively charged layers

Because of their negative charge, they repel each other, allowing water to pass through

In this way, when the bundle swells, a stable crust forms around the platelets

When saturated, this crust will repel water, even under pressure

Because of all these properties, bentonite is used in ponds and ponds, to seal soil seeps and lining the base of landfills

non explosive rock breaking chemicals

Today they use non-explosive rock breaking chemicals in mining industries

Conventional blasting has several drawbacks

Drilling, blasting and reaming operations are complex; Personnel and equipment must be evacuated prior to detonation; safety hazard; The environment was negatively affected

In addition, the use of blasting methods near residential and populated areas requires strict procedures and precautions, which mainly affects the continuity of the rock drilling process

To overcome the disadvantages of conventional blasting and ensure the continuity of the rock exploration process, many modern methods have been developed as practical solutions for rock breaking in accordance with safe and environmentally friendly operating standards

The use of conventional methods of destruction, such as explosives, may not be possible or require special precautions

Non-explosive chemicals operates in a variety of situations where conventional explosives are prohibited or unwanted

Non-explosive chemicals is a safe, non-explosive and cost-effective demolition solution

It can also reduce labor costs and increase productivity while drastically reducing environmental impacts

Newly developed technologies were introduced as unconventional methods for drilling hard rock and concrete and as alternatives to the explosive blasting method

The application of these modern methods in the field of mining also contributes to the continuity of the drilling process, reduces mineral dilution and mineral losses, reduces the amount of labor required and ensures safe conditions for mining operations

Some modern methods such as pumped water and high-pressure gas systems have been reviewed and compared

Hydraulic fluid has been patented for use in hard rock fracturing and has been shown to be effective

Furthermore, extended chemical agents have been identified for the same purposes

Here, the hydraulic splitting method and extended chemical agents are reviewed, highlighting the process of action, applications, and potential efficacy

betonamit price

Betonamit price for sale / 5 kg bag is $57

83

Betonamit has been used safely and with excellent results by thousands of contractors and homeowners around the world

Safe use relies on following the instructions and wearing safety glasses at all times

Although bituminous is non-toxic, it is caustic and can cause serious eye injury if splashed in the eye during mixing or pouring

The chemical reaction of betonamate and water generates heat

If this reaction proceeds too quickly, the temperature can rise above the boiling point of water before all of the water chemically combines with the bitonamite

This can result in a steam-driven explosion that expels bitonamite from the crater with sudden force

To avoid bursting, follow directions for mixing water temperatures and hole sizes

Always wear protective eyewear and do not use piercings larger than 1 1/2 inches in diameter

Blow dust out of holes after drilling and keep bitumen emulsion cool before use

The features of the holes to put bitonamite are as follows:

Maximum hole depth is 10 feet

The minimum depth of the hole is 4 times the diameter of the hole

For example, 5 with a 1-1/4″ hole, 6 with a 1-1/2″ hole

Holes less than 4 times the diameter are more likely to burst

In reinforced concrete, 85-90% of its depth is drilled

At the edge, dig as deep as you like to remove it

In rocks, drill 2/3 to 3/4 of the thickness of the rock

betonamit instructions

There are a few instructions on how to use betonamite

The first step is to drill 1¼”-1” diameter holes

The optimal distance between each well is about 10 times its diameter, and therefore about 30-40 cm

Wells must be clean and dry

Now put BETONAMIT® powder into the mixing bowl

Add 1

0 max

1

2 liters (per 5 kg) of clean cold water

Blend it with a mixer until it becomes a smooth and homogeneous mixture

Fill the well with the mixture directly

The processing time should not exceed 5 minutes

No additional mechanical seal is required

The following is the list of the holes patterns you need to follow in your instructions

Holes should be drilled to allow a free face of bit bentonite clay to rush into it

For example, drilling at a 45-degree angle into a flat surface from the edge will push it up, but drilling straight down may not allow any places to compress

To demolish a slab without pushing on the surrounding walls, drill a cone-shaped pattern in the center and fill these holes first

The cone will pop up and create a free face

The hole pattern depends on the tensile strength of what you’re breaking, the number of rebars, if any, and the size of the pieces you want when you’re done

This can often be determined by experience; A good starting point is to place holes one foot on center in rows one and a half feet apart on center

In unreinforced concrete, holes can be spaced up to 24 degrees apart

Hole pattern also depends on how quickly you need results

More holes together will have faster break times and smaller pieces, but this costs more to work with and betonamate

Rock is much easier to break than reinforced concrete or edges, and drill holes can be more widely spaced, especially if breaking speed is not critical

When removing part of the slab, you must prevent cracks from spreading to the rest of the slab

Drill 6 holes in the center on a line between the “demolition” section and the “retention” section, then fill every third hole

The empty holes form weaknesses and prevent cracks from propagating in the “retainer” section

Empty holes can also be used to guide slits; its cost is less than filled holes

For example, if you want to divide a rock into thirds, you can use this pattern